James Instruments IQM-Meter

The James IQM System enables fresh concrete to be easily and completely monitored in the field for improved safety, quality assurance and optimum setting time.

Designed specifically for monitoring and analyzing fresh concrete, the IQM Module is programmed with the required Equivalent Age of the concrete under test. Once this preset maturity number is reached, i visual indicator will flash continuously, providing an effective, automatic indication that the concrete has reached the desired level of maturity.

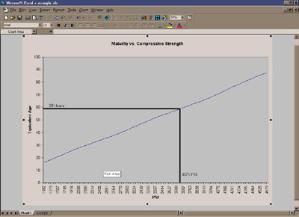

Software and interface cables allow direct uploading of the data to a WIndows PC environment where it can be imported into any spreadsheet, word processor or graphing program for further analysis. Temperature history can be graphically displayed with respect to time.

The IQM software will create maturity indices from the complex Arrhenius equation according to ASTM procedure. The strength gain can be calculated and all these parameters can be graphically displayed with respect to time. The James IQM System enables fresh concrete to be easily and completely monitored in the field for improved safety, quality and optimum stripping time. Its modular design facilitates number and choice of monitoring locations.

The system generally consists of multiple units of M-IQM-4011 units on the structure logging the temperature and programmed with the proper activation energies. These monitor the critical and most temperature sensitive area's of the structure. Each unit is connected to a single thermocouple (M-IQT-4011). The units are then programmed with the M-IQM-4040 software and a PC. Once the concrete has reached the proper cure point the temperature history can be retrieved with the software (M-IQM-4040). This makes the IQM System flexible to accomodate a single location or multiple locations on a structure.

Features & Benefits:

Specifications

| Model M-IQM-4010 | K-Thermocouple Module |

| Memory SIze: | > 8000 Data Points |

| Memory Type: | Non-Volatile |

| Battery Type: | 1-9 V Battery |

| Battery Life: | @ 20°C: 30 Days recording every 30 minutes |

| Intervals Between Readings: | From 1 minute to 24 hours in Minute increments |

| Recording Temperature Range: | -20°C to 100° C |

| Dimensions: | 1.5 x 2.5 x 5 inches (38mm x 63x 127mm) |

| Weight: | 10 oz (280 grams) |

| Model M-IQM-4011 | 3 Ft (1 m) Thermocouple (included with every M-IQM-4010 System accuracy ± 1°C |

| Model M_IQM-4040 | Software to calculate maturity and strength |

| Operating System: | Windows 9x/ ME |

| Processor: | 166 MHz Pentium or faster |

| Ram: | 32 MB |

| Hard Disk: | 8 MB |